Schnabel-Prototyping

INSTRUMENT CLUSTER GEAR FOR MERCEDES G G-CLASS W460 W461 SPEEDOMETER M10 10-tooth

INSTRUMENT CLUSTER GEAR FOR MERCEDES G G-CLASS W460 W461 SPEEDOMETER M10 10-tooth

SKU:30002

Couldn't load pickup availability

M10 gear for Mercedes G G-Class W460 VDO speedometer repair

excellent workmanship

Description:

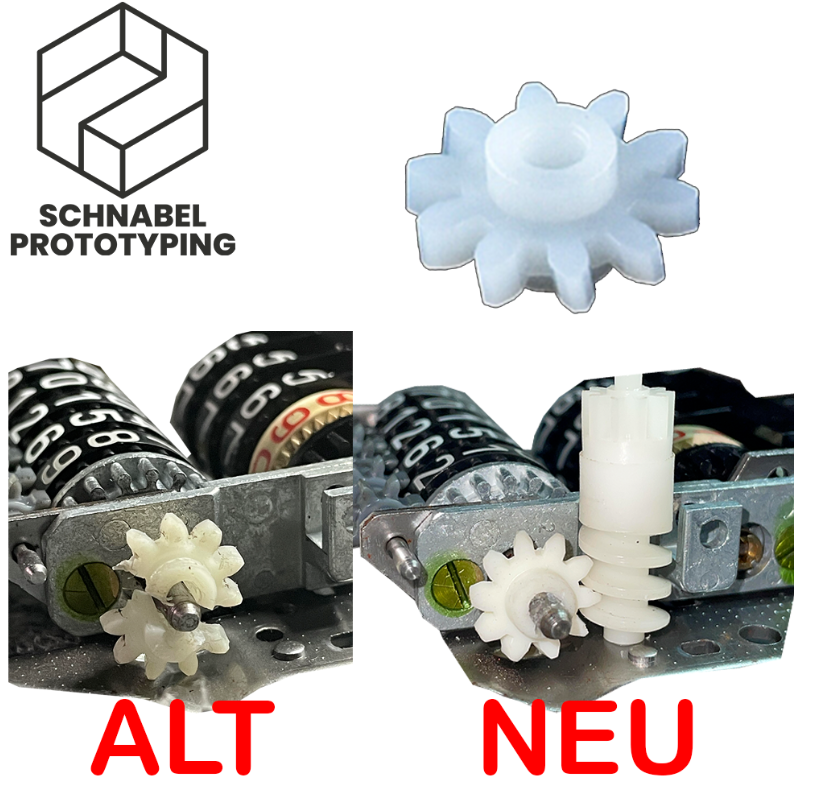

If your vehicle's odometer/trip meter has failed, the gear shown in the picture is usually the cause. The second most common cause is a smaller, wider gear on the worm shaft.

A notice:

The G model has a second, wider gear, which often fails. Unfortunately, we don't have a replacement for this yet. Therefore, please check which gear you need BEFORE purchasing.

Important:

Unfortunately, the assignment between engine type/gearbox type/year of manufacture/model/country type and gear type is so complex that only counting the teeth provides 100% certainty.

We strongly recommend disassembling the speedometer before purchasing and notifying us of the number of teeth in the comments when purchasing. This will prevent a replacement. Without this information, you will receive the most commonly installed gear for this vehicle type.

Service:

We have over 100 gear wheel variants in our range and can supply the matching gear wheels if required!

+ all alternative sizes always in stock

+ fast exchange service in case of size discrepancy

Quality:

Our gears are painstakingly manufactured using injection molding techniques, true to the original, and are not 3D printed in-house. We work with a manufacturer that specializes in the production of plastic gears and is the global market leader in its repair solutions.

The so-called involute tooth geometry is retained; this is the only way to ensure low-friction sliding of the tooth flanks between the gear pairs.

We use the thermoplastic Celron with graphite additives as the material. These ensure low friction and wear-free operation.

If you disassemble the speedometer beforehand, please note that the speedometer needle shaft is very delicate. Grasp the speedometer needle in the middle and turn it counterclockwise, pulling gently. Friction is all that keeps the needle on the shaft.

Share